OPENERS | COMMERCIAL

Opera – MJ (O M J)

Medium-Duty Jackshaft Operator With Floor Level Disconnect

14 CYCLES/HOUR 50 CYCLES/DAY

APPLICATIONS

The Opera-MJ is a medium-duty operator designed for use on standard, high and vertical lift sectional doors or rolling doors(1) and grilles.

The operator can be wall, hood, or shelf mounted on either side of the door. It incorporates a floor level disconnect mechanism for manual operation.

The operator is available with the new Electronic Control Board (BOARD 070) with or without the option of electrical control for MONITORED external entrapment protection devices (UL325-2010 compliant).

STANDARD FEATURES

- Motor: 1/2 HP, 120V single phase intermittent-duty motor with instant reverse and internal automatic reset thermal overload protection. Removable without affecting limit switch settings. Also available with 50Hz motor, consult inside sales.

- Reduction: First step in reduction 5L/B V-belt drive, additional steps by chain and sprockets. Input shaft is 5/8″, supported by precision ball bearings. Output shaft is 1″ with 1/4″ keyway, supported by ball bearings. Output shaft speed: 36 rpm.

- Clutch: Friction type, positioned on input shaft, easily adjustable from outside.

- Drive: #41 roller chain with a 41B12 sprocket on operator drive shaft. Door sprocket selected for a door travel of 6″/s to 12″/s.

- Brake: Mechanical brake.

- Manual Operation: Floor level disconnect mechanism which must be engaged for manual push-up operation.

- Electrical Enclosure: All electrical components are in a Nema 1 enclosure. Hinged electrical enclosure cover.

- Limit System: Rotary-type oil-impregnated steel cams, commercial grade switches. Limit shaft is supported by self-lubricating bronze bushings for increased precision. Remains in time when there is a manual operation or after the motor has been removed.

- Accu-cam® Feature: Precise and quick one-handed adjustment of the limits.

- Corrosion Protection: Frame and control enclosure protected by baked on, long lasting enamel finish. Polymer control box cover. All shafts protected by yellow chromate coating.

- Mounting: Wall, hood, or shelf mounted on the right or on the left of the door. For indoor use only.

- Dimensions:

Clearance: side room required 15″ (380 mm)

Maximum Door Height: 14″ (4260 mm)

For more details, please consult our Dimensions Drawing. - Shipping Weight: Approx. 60 Lbs – 27 Kg.

- Warranty: 2 Years.

CONTROL OPTIONS

- ECB Units (BOARD 070):

24VDC relaying circuit with a 40VA class II transformer, non-volatile memory. Features available: On-board radio receiver, 1.5s delay on reverse, programmable maximum run timer, mid-stop, timer to close (suspension possible from floor level), independent input loop terminal, advance close system, test buttons, reverse wiring detection and door lock sensor. Operating mode selectable on site: C2, B2, D1, E2, T or TS.

- Electronic Monitored (M) Version: Provides the monitoring of Primary External Entrapment Protection Devices. Includes monitored photo cells (PHOTO 070 standard). In this mode, Ancillary Entrapment Protection Devices (optional) may be used to supplement primary entrapment protection, such as non-monitored photo cells, 2-wire non-monitored sensing edges and pneumatic sensing edges.

Certifications: CSA C22.2-247.92 and UL325. - Electronic (E) Version:

No monitoring function.

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision. - Contactor Units: 24VAC control circuit, 40VA class II transformer, fuse protected on output, heavy-duty across-the-line linear reversing contactor with mechanical interlock.

- B2/C2 Units: C2 wiring is standard. B2 can be set very easily by moving one wire. Available options: delay on reverse, timer to close, double limits, etc...

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision.

Note: CSA C22.2-247.92 and UL325 apply to units intended to be used in ordinary locations in accordance with the Canadian Electrical Code, Part I and the National Electrical Code, NFPA 70, respectively.

MAIN OPTIONS

- Control Accessories: Angled terminal strip allows for the connection of 3-button stations (one supplied with the operator), non-monitored sensing edges, non-monitored photo cells, one push-button radio control(external strip), ceiling pull switches, key switches, loop detectors, external interlocks and universal auxiliary output module. 2A fuse protected 24VAC output is available for accessory power supply. NEMA 4/12 or NEMA 4X protected monitored photo cells upgrade available.

- Mechanical Accessories: Wall or hood mounting bracket, chain spreader, etc…consult inside sales.

- Mechanical Modifications:

#50 roller chain and sprocket on final drive and limit shaft speed-up, etc… consult inside sales.

(1) For properly balanced rolling steel doors with less than 80 lbs of imbalance, rolling sheet doors, vinyl doors or equivalents. For larger rolling doors, we recommend using an electrically activated drum-band type solenoid brake, see Mechanical Modifications.

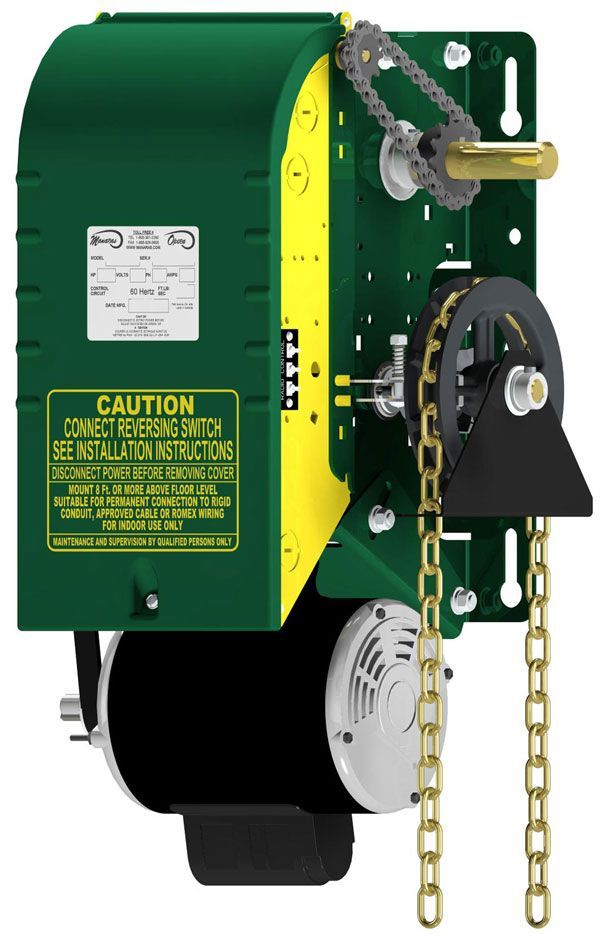

Opera – GH (O G H)

Heavy-Duty Industrial Gear Head Operator With Hoist

25 CYCLES/HOUR >80 CYCLES/DAY

APPLICATIONS

The Opera-GH is a heavy-duty worm gear industrial operator designed for use on industrial standard, high and vertical lift sectional doors or rolling doors and grilles.

The operator can be wall, hood, or shelf mounted on either side of the door. It incorporates the patented Hoist-a-matic®, a self-engaging chain hoist for manual operation, which simplifies operation and installation.

The operator is available with the new Electronic Control Board (BOARD 070) with or without the option of electrical control for MONITORED external entrapment protection devices (UL325-2010 compliant).

STANDARD FEATURES

- Motor: 60Hz high starting torque, continuous-duty, single phase capacitor start or 3 phase motor, open drip proof with enclosed ends or drip cover, protected against overload. Also available with 50Hz 220V 1 phase and 380V 3 phase motor, consult inside sales.

- Reduction: 45:1 worm gear in oil bath reducer with air breather and sealed ball bearings. Output shaft is 1″ with 1/4″ keyway up to 1HP, 1-1/4″ output shaft with 1/4″ keyway above 1HP. Output shaft speed: 38 rpm.

- Drive: #50 roller chain with a 50B12 sprocket for the operator drive shaft. Door sprocket selected for a door travel of 6″/s to 12″/s.

- Brake: Electrically activated drum-band type solenoid brake.

- Manual Operation: Hoist-a-matic® self-engaging hoist (floor level engagement device is not required to operate) for manual chain operation. An electrical interlock automatically disconnects power to the motor operator when the the chain hoist is engaged. Hoist on right is standard, but it can be easily moved to the left in the field.

- Electrical Enclosure: All electrical components are in a Nema 1 enclosure. Hinged electrical enclosure cover.

- Limit System: Rotary-type oil-impregnated steel cams, commercial grade switches. Limit shaft is supported by self-lubricating bronze bushings for increased precision. Remains in time when there is a manual operation or after the motor has been removed.

- Accu-cam® Feature: Precise and quick one-handed adjustment of the limits.

- Corrosion Protection: Reducer, control enclosure and frames protected by baked on, long lasting enamel finish. Polymer control box cover. Limit and hoist shaft protected by yellow chromate coating.

- Mounting: Wall mounted, vertical front of hood mounted or horizontal top of hood mounted, on the right or on the left of the door. The use of a wall mounting bracket is recommended. For indoor use only.

- Dimensions:

Clearance: side room required 15″ (380 mm)

With Friction Clutch Add: 1.5″ (38 mm)

For more details, please consult our Dimensions Drawing. - Shipping Weight: Approx. 122 Lbs – 55 Kg.

- Warranty: 2 Years.

CONTROL OPTIONS

- ECB Units (BOARD 070): 24VDC relaying circuit with a 40VA class II transformer, non-volatile memory. Features available: On-board radio receiver, 1.5s delay on reverse, programmable maximum run timer, mid-stop, timer to close (suspension possible from floor level), independent input loop terminal, advance close system, test buttons, reverse wiring detection and door lock sensor. Operating mode selectable on site: C2, B2, D1, E2, T or TS.

- Electronic Monitored (M) Version:

Provides the monitoring of Primary External Entrapment Protection Devices. Includes monitored photo cells (PHOTO 070 standard). In this mode, Ancillary Entrapment Protection Devices (optional) may be used to supplement primary entrapment protection, such as non-monitored photo cells, 2-wire non-monitored sensing edges and pneumatic sensing edges.

Certifications: CSA C22.2-247.92 and UL325 5th Ed. PRIOR to August 2010 revision. - Electronic (E) Version: No monitoring function.

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision. - Contactor Units: 24VAC control circuit, 40VA class II transformer, fuse protected on output, heavy-duty across-the-line linear reversing contactor with mechanical interlock.

- B2/C2 Units:

C2 wiring is standard. B2 can be set very easily by moving one wire. Available options: delay on reverse, timer to close, double limits, etc...

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision.

Note: CSA C22.2-247.92 and UL325 apply to units intended to be used in ordinary locations in accordance with the Canadian Electrical Code, Part I and the National Electrical Code, NFPA 70, respectively.

MAIN OPTIONS

- Control Accessories: Angled terminal strip allows for the connection of 3-button stations (one supplied with the operator), non-monitored sensing edges, non-monitored photo cells, one push-button radio control (external strip), ceiling pull switches, key switches, loop detectors, external interlocks and universal auxiliary output module. 2A fuse protected 24VAC output is available for accessory power supply. NEMA 4/12 or NEMA 4X protected monitored photo cells upgrade available.

- Friction Clutch (Optional): Easily adjustable slip clutch, ideally positioned on output shaft. Recommended for sectional doors.

- Mechanical Accessories: Wall or hood mounting bracket, chain spreader, hand crank, etc…consult inside sales.

- Mechanical Modifications: Left hand chain hoist, #60 roller chain and sprocket on final drive, limit shaft speed-up, etc…consult inside sales.

Opera – H (O P H)

Heavy-Duty Commercial Jackshaft Operator With Hoist

25 CYCLES/HOUR 100 CYCLES/DAY

APPLICATIONS

The Opera-H is a heavy-duty industrial operator designed for use on standard, high and vertical lift sectional doors or rolling doors(1) and grilles.

The operator can be wall, hood, or shelf mounted on either side of the door. It incorporates the patented Hoist-a-matic®, a self-engaging chain hoist for manual operation, which simplifies operation and installation.

The operator is available with the new Electronic Control Board (BOARD 070) with or without the option of electrical control for MONITORED external entrapment protection devices (UL325-2010 compliant).

STANDARD FEATURES

- Motor: 60Hz high starting torque, continuous-duty, single phase capacitor start or 3 phase motor, open drip proof, protected against overload. Also available with 50Hz 220V 1 phase and 380V 3 phase motor, consult inside sales.

- Reduction: First step in reduction 5L/B V-belt drive, additional steps by chain and sprockets. Input shaft is 5/8″, supported by precision ball bearings. Output shaft is 1″ with 1/4″ keyway, supported by ball bearings. Output shaft speed: 41 rpm.

- Clutch: Friction type, positioned on input shaft, easily adjustable from outside.

- Drive: #50 roller chain with a 50B12 sprocket for the operator drive shaft. Door sprocket selected for a door travel of 6″/s to 12″/s.

- Brake: Mechanical brake.

- Manual Operation: Hoist-a-matic® self-engaging hoist (floor level engagement device is not required to operate) for manual chain operation. An electrical interlock automatically disconnects power to the motor operator when the chain hoist is engaged. Hoist on right is standard.

- Electrical Enclosure: All electrical components are in a Nema 1 enclosure. Hinged electrical enclosure cover.

- Limit System: Rotary-type oil-impregnated steel cams, commercial grade switches. Limit shaft is supported by self-lubricating bronze bushings for increased precision. Remains in time when there is a manual operation or after the motor has been removed.

- Accu-cam® Feature: Precise and quick one-handed adjustment of the limits.

- Corrosion Protection: Frame and control enclosure protected by baked on, long lasting enamel finish. Polymer control box cover. All shafts protected by yellow chromate coating.

- Mounting: Wall, hood, or shelf mounted on the right or on the left of the door. For indoor use only.

- Dimensions:

Clearance: side room required 15″ (380 mm)

For more details, please consult our Dimensions Drawing. - Shipping Weight: Approx. 86 Lbs – 39 Kg.

- Warranty: 2 Years.

CONTROL OPTIONS

- ECB Units (BOARD 070): 24VDC relaying circuit with a 40VA class II transformer, non-volatile memory. Features available: On-board radio receiver, 1.5s delay on reverse, programmable maximum run timer, mid-stop, timer to close (suspension possible from floor level), independent input loop terminal, advance close system, test buttons, reverse wiring detection and door lock sensor. Operating mode selectable on site: C2, B2, D1, E2, T or TS.

- Electronic Monitored (M) Version:

Provides the monitoring of Primary External Entrapment Protection Devices. Includes monitored photo cells (PHOTO 070 standard). In this mode, Ancillary Entrapment Protection Devices (optional) may be used to supplement primary entrapment protection, such as non-monitored photo cells, 2-wire non-monitored sensing edges and pneumatic sensing edges.

Certifications: CSA C22.2-247.92 and UL325. - Electronic (E) Version: No monitoring function.

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision. - Contactor Units: 24VAC control circuit, 40VA class II transformer, fuse protected on output, heavy-duty across-the-line linear reversing contactor with mechanical interlock.

- B2/C2 Units:

C2 wiring is standard. B2 can be set very easily by moving one wire. Available options: delay on reverse, timer to close, double limits, etc…

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision.

Note: CSA C22.2-247.92 and UL325 apply to units intended to be used in ordinary locations in accordance with the Canadian Electrical Code, Part I and the National Electrical Code, NFPA 70, respectively.

MAIN OPTIONS

- Control Accessories: Angled terminal strip allows for the connection of 3-button stations (one supplied with the operator), non-monitored sensing edges, non-monitored photo cells, one push-button radio control (external strip), ceiling pull switches, key switches, loop detectors, external interlocks and universal auxiliary output module. 2A fuse protected 24VAC output is available for accessory power supply. NEMA 4/12 or NEMA 4X protected monitored photo cells upgrade available.

- Environmental Modifications: NEMA 4/12 and NEMA 4X enclosures. For NEMA 7/9, consult inside sales.

- Mechanical Accessories: Wall or hood mounting bracket, chain spreader, etc…consult inside sales.

- Mechanical Modifications:

Left hand chain hoist, electrically activated drum-band type solenoid brake, cast iron flanged pillow block bearings on output shaft, limit shaft speed-up, etc…consult inside sales.

(1) For properly balanced rolling steel doors with less than 80 lbs of imbalance, rolling sheet doors, vinyl doors or equivalents. For larger rolling doors, we recommend using an electrically activated drum-band type solenoid brake, see Mechanical Modifications.

Opera – MH (O M H)

Medium-Duty Jackshaft Operator With Hoist

14 CYCLES/HOUR 50 CYCLES/DAY

APPLICATIONS

The Opera-MH is a medium-duty operator designed for use on standard, high and vertical lift sectional doors or rolling doors(1) and grilles.

The operator can be wall, hood, or shelf mounted on either side of the door. It incorporates the patented Hoist-a-matic®, a self-engaging chain hoist for manual operation, which simplifies operation and installation.

The operator is available with the new Electronic Control Board (BOARD 070) with or without the option of electrical control for MONITORED external entrapment protection devices (UL325-2010 compliant).

STANDARD FEATURES

- Motor: 1/2 HP, 120V single phase intermittent-duty motor with instant reverse and internal automatic reset thermal overload protection. Removable without affecting limit switch settings. Also available with 50Hz motor, consult inside sales.

- Reduction: First step in reduction 5L/B V-belt drive, additional steps by chain and sprockets. Input shaft is 5/8″, supported by precision ball bearings. Output shaft is 1″ with 1/4″ keyway, supported by ball bearings. Output shaft speed: 36 rpm.

- Clutch: Friction type, positioned on input shaft, easily adjustable from outside.

- Drive: #41 roller chain with a 41B12 sprocket for the operator drive shaft. Door sprocket selected for a door travel of 6″/s to 12″/s.

- Brake: Mechanical brake.

- Manual Operation: Hoist-a-matic® self-engaging hoist (floor level engagement device is not required to operate) for manual chain operation. An electrical interlock automatically disconnects power to the motor operator when chain hoist is engaged. Hoist on right is standard.

- Electrical Enclosure: All electrical components are in a Nema 1 enclosure. Hinged electrical enclosure cover.

- Limit System: Rotary-type oil-impregnated steel cams, commercial grade switches. Limit shaft is supported by self-lubricating bronze bushings for increased precision. Remains in time when there is a manual operation or after the motor has been removed.

- Accu-cam® Feature: Precise and quick one-handed adjustment of the limits.

- Corrosion Protection: Frame and control enclosure protected by baked on, long lasting enamel finish. Polymer control box cover. All shafts protected by yellow chromate coating.

- Mounting: Wall, hood, or shelf mounted on the right or on the left of the door. For indoor use only.

- Dimensions:

Clearance: side room required 15″ (380 mm)

Maximum Door Height: 14″ (4260 mm)

For more details, please consult our Dimensions Drawing. - Shipping Weight: Approx. 68 Lbs – 31 Kg.

- Warranty: 2 Years.

CONTROL OPTIONS

• ECB Units (BOARD 070):

24VDC relaying circuit with a 40VA class II transformer, non-volatile memory. Features available: On-board radio receiver, 1.5s delay on reverse, programmable maximum run timer, mid-stop, timer to close (suspension possible from floor level), independent input loop terminal, advance close system, test buttons, reverse wiring detection and door lock sensor. Operating mode selectable on site: C2, B2, D1, E2, T or TS.

• Electronic Monitored (M) Version:

Provides the monitoring of Primary External Entrapment Protection Devices. Includes monitored photo cells (PHOTO 070 standard). In this mode, Ancillary Entrapment Protection Devices (optional) may be used to supplement primary entrapment protection, such as non-monitored photo cells, 2-wire non-monitored sensing edges and pneumatic sensing edges.

Certifications: CSA C22.2-247.92 and UL325.

• Electronic (E) Version:

No monitoring function.

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision.

• Contactor Units:

24VAC control circuit, 40VA class II transformer, fuse protected on output, heavy-duty across-the-line linear reversing contactor with mechanical interlock.

• B2/C2 Units:

C2 wiring is standard. B2 can be set very easily by moving one wire. Available options: delay on reverse, timer to close, double limits, etc…

Certifications: CSA C22.2-247.92 and compliant to UL325 5th Ed. PRIOR to August 2010 revision.

Note: CSA C22.2-247.92 and UL325 apply to units intended to be used in ordinary locations in accordance with the Canadian Electrical Code, Part I and the National Electrical Code, NFPA 70, respectively.

MAIN OPTIONS

• Control Accessories:

Angled terminal strip allows for the connection of 3-button stations (one supplied with the operator), non-monitored sensing edges, non-monitored photo cells, one push-button radio control (external strip), ceiling pull switches, key switches, loop detectors, external interlocks and universal auxiliary output module. 2A fuse protected 24VAC output is available for accessory power supply. NEMA 4/12 or NEMA 4X protected monitored photo cells upgrade available.

• Mechanical Accessories:

Wall or hood mounting bracket, chain spreader, etc…consult inside sales.

• Mechanical Modifications:

Left hand chain hoist, #50 roller chain and sprocket on final drive and limit shaft speed-up, etc… consult inside sales.

- (1) For properly balanced rolling steel doors with less than 80 lbs of imbalance, rolling sheet doors, vinyl doors or equivalents. For larger rolling doors, we recommend using an electrically activated drum-band type solenoid brake, see Mechanical Modifications.

T – LiftMaster

Smart

- My Q® technology enables monitoring and control of the facility operators through a mobile app.

- Grid View to efficiently monitor all the doors in the facility.

- Real-time alerts indicate the status of doors via email or push notifications.

Safe & Secure

- Security + 2.0® safeguards facility access with rolling code technology, opening for registered devices only.

- Timer-to-close can be programmed to close the door after a set amount of time.

- The commercial Protector System® auto-reverses the door if an entrapment protection device detects an obstruction.

Reliable

- Continuous-duty high-starting torque motor performs in demanding industrial overhead door applications.

- Warranty 2-years.

- Beyond industry standards: LIFTMASTER® is committed to quality products, innovative design and comprehensive services.

MT- LiftMaster

Proven Performance

- Medium-duty logic programmable integrated circuit board.

- Built-In-3-Channel Security+® Receiver.

- Allows you to learn/program up to (20) LIFTMASTER® 315 MHz remote controls.

- Recognizes security+ and dip switch remote controls.

- Compatible with 3-button, 3-color remote controls for open, close/stop operation. (333LM)

Safe & Secure

- Integrated timer-to-close can (TTC) programmable from 5 to 60 seconds in 5-second increments.

- Allows for timed automatic door closure after the door reaches the full open position.

- Emergency manual operation floor level disconnect enables emergency manual operation.

- The commercial protector system auto-reverses the closing door if an entrapment protection device detects an obstruction.

Reliable

- High-starting torque motor with overload protection.

- Warranty 2-years.

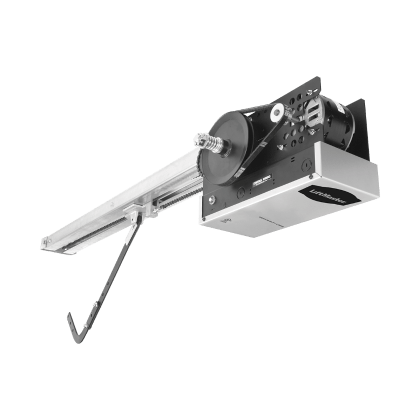

MJ – LiftMaster

Proven Performance

- Medium-duty logic programmable integrated circuit board.

- Built-In-3-Channel Security+® Receiver.

- Allows you to learn/program up to (20) LIFTMASTER® 315 MHz remote controls.

- Recognizes security+ and dip switch remote controls.

- Compatible with 3-button, 3-color remote controls for open, close/stop operation. (333LM)

Safe & Secure

- Integrated timer-to-close can (TTC) programmable from 5 to 60 seconds in 5-second increments.

- Allows for timed automatic door closure after the door reaches the full open position.

- Emergency manual operation floor level disconnect enables emergency manual operation.

- The commercial protector system auto-reverses the closing door if an entrapment protection device detects an obstruction.

Reliable

- High-starting torque motor with overload protection.

- Warranty 2-years.

J – LiftMaster

Reliable

- Continuous-duty high-starting torque motor performs in demanding industrial overhead and rolling door applications.

- Warranty 2 Years.

- Beyond industry standards: LIFTMASTER® is committed to quality products, innovative design and comprehensive services.

Smart

- MyQ® Technology enables monitoring and control of the facility operators through a mobile app.

- Grid View to efficiently monitor all the doors in the facility.

- Real-time alerts indicate the status of doors via email or push notifications.

- Connectivity requires purchase of internet gateway (828LM) or MyQ home bridge (819LMB), sold separately.

Safe & Secure

- Security+ 2.0® safeguards facility access with rolling code technology, opening for registered devices only.

- Timer-to- close can be programmed to close the door after a set amount of time.

- The commercial protector system® auto-reverses the door if an entrapment protection device detects an obstruction.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

HCTDCUL – LiftMaster

Product Highlights

- Designed to increase uptime and deliver reliable and powerful performance

- The noise-isolating design provides exceptionally smooth and quiet operation.

- Selectable speed control opens up to 11 “per second to keep traffic flowing.

- Continuous-duty high-starting torque motor performs in demanding industrial overhead and rolling door applications.

- Up to 72 days of standby power or 112 cycles when the power is down.

- Security+2.0®3-channel receiver will handle up to 50 remote controls (unlimited remotes with 811LM/813LM).

- Allows gate to auto open upon loss of AC power or battery depletion.

- Can be programmed with anti-tailgate or quick close capabilities.

GH – LiftMaster

Reliable

- Continuous-duty high-starting torque motor performs in demanding industrial overhead and rolling door applications.

- Warranty 2 Years.

- Beyond industry standards: LIFTMASTER® is committed to quality products, innovative design and comprehensive services.

Smart

- MyQ® Technology enables monitoring and control of the facility operators through a mobile app.

- Grid View to efficiently monitor all the doors in the facility.

- Real-time alerts indicate the status of doors via email or push notifications.

- Connectivity requires purchase of internet gateway (828LM) or MyQ home bridge (819LMB), sold separately.

Safe & Secure

- Security+ 2.0® safeguards facility access with rolling code technology, opening for registered devices only.

- Timer-to- close can be programmed to close the door after a set amount of time.

- The commercial protector system® auto-reverses the door if an entrapment protection device detects an obstruction.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

We're here when you need us

New Paragraph

BUSINESS HOURS

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- -

- Sunday

- Closed

QUICK LINKS

Services

Openers

© Power Garage Doors, Inc